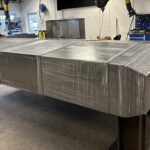

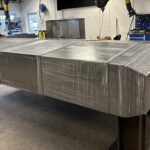

Before and after refurbishing

With over 30 years of experience in refurbishing machine protective covers, Damaskus Maskinskydd possesses possibly Sweden’s largest knowledge bank about protective covers for machine tools. We mainly refurbish telescopic covers, but also other types of machine protection such as role-up covers and folding partition walls. We do everything from simple service and maintenance to advanced repairs where one or more parts are newly manufactured in our workshop. We always review the cover when it comes to us, and then give you a price and delivery time.

Refurbishing a telescopic cover can be up to 60% cheaper than buying a new one. In addition, some newly manufactured covers may have a 12 week delivery time, and a refurbishment takes about 1-2 weeks. This means that the savings are even greater in reduced production downtime.

Most people are aware that refurbishing telescopic covers is a good decision financially, but many are not aware that there is an environment friendly aspect to consider. The vast majority of telescopic covers can be refurbished four to six times, meaning less material and energy needs to be used and transport over long distances can be avoided. When a cover no longer can be refurbisched, we sort the metal to be recycled. A refurbishment is thus a way for our customers to take responsibility for the environment and together we contribute to the circular economy.

For all covers we refurbish, we:

• Renew or replacement of damaged sections

• Renew or replacement of damaged scissors

• Replace riders and guide rollers

• Replace brass guides

• Replace wipers

• Cleaning and buffing to original finish

• Test controls before delivery