Cutting with water has many advantages. Waterjet cutting is a cold machining process with high precision, meaning that the properties of the material are not affected during the cutting, no stresses are induced in the material, material waste is minimized, and the cut surface rarely needs any post-processing.

It is also an environmentally friendly method without harmful chemicals or fumes, where the only byproducts aside from material particles are water and sand.

Our waterjet cutting machine from Water Jet Sweden has a working area of 3000 x 2000 mm and dual cutting heads, providing high working capacity and cost-efficiency suitable for larger series.

Materials suitable for waterjet cutting include steel, stainless steel, Hardox, aluminum, copper, brass, titanium, composite materials, rubber, plastic, etc.

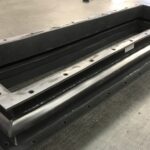

To enable fast deliveries, we have a large stock of materials. We also perform post-processing and deliver, if desired, fully machined components that may include bending, milling, threading, and surface treatment. We have extensive experience in vulcanizing rubber and metal parts together, such as the special bellows below with aluminum flanges.

We systematically document all completed work and can guarantee identical copies from previous deliveries. Do not hesitate to ask us how we can help you realize your ideas and projects.

Other typical rubber products we produce in our water jet is seals, rubber protection etc.